[industrial packaging design] (dry goods) steel belt box technical data

2024-01-31

Fast packing is also called steel side box. It has a series of advantages such as reliable connection, beautiful appearance, reusable, lightweight, and easy loading and unloading. It is widely used abroad and is often used in the packaging of export products. The appearance is smooth, smooth and beautiful, strong and durable, according to the customer's requirements of the packing box for spray painting or printing mark LOGO, it will be folded after storage, greatly reducing the transportation cost.

![[industrial packaging design] (dry goods) steel belt box technical data [industrial packaging design] (dry goods) steel belt box technical data](/npublic/img/s.png)

Fast packing is also called steel side box. It has a series of advantages such as reliable connection, beautiful appearance, reusable, lightweight, and easy loading and unloading. It is widely used abroad and is often used in the packaging of export products. The appearance is smooth, smooth and beautiful, strong and durable, according to the customer's requirements of the packing box for spray painting or printing mark LOGO, it will be folded after storage, greatly reducing the transportation cost.

It adopts a special structure of galvanized steel strip combined with tongue-shaped lock buckle, and combines six plywood panels. It is a foldable and detachable plywood packing box. The connecting parts are stamping-grade cold-rolled galvanized steel strip and tongue-shaped fasteners. The plates used are multi-layer plywood made of artificial composite. The bearing capacity far exceeds that of wood, so as to ensure the quality of the packing box is strong and durable, and the whole process protects the goods in the box. The exterior shape is smooth, and beautiful, it has the characteristics of low cost, large carrying capacity, not afraid of sun, rain, and no moths.

According to the weight of the contents of different, the use of different plate thickness, common thickness of 6mm, 7mm, etc.

There are usually two kinds of structures:

Structure 1

Commonly known as the three-piece box, respectively, the bottom of the box, the side plate connected by the flexible steel edge and the box cover, suitable for product packaging with a height of not more than 800mm.

Structure 2

Commonly known as a six-piece box, it consists of six components such as a box bottom, two side panels, two end panels and a box cover. It is usually suitable for some large product packaging, and small ones can also be used.

Features:

1. It is connected by high-strength galvanized steel strips, excellent load-bearing and compression resistance, and more durable

2. More light, beautiful, can spray printing, enhance customer product image

3. The weight is only 30% ~ 40% of traditional products, and has good stack performance

4. Excellent climate tolerance, adapt to various harsh climates from tropical to frigid

5. Suitable for long-term transportation and storage, can be reused many times

6. Can be arbitrarily disassembled, effectively saving storage space, reduce transportation costs

7. To meet the heavy, large, transport sensitive and high value of the product transport packaging requirements

8. Meet the requirements of commodity export packaging quarantine inspection, for export inspection-free products

9. can be processed according to customer demand arbitrary specifications, size

10. Can quickly and conveniently carry out on-site assembly or disassembly of items, especially large boxes.

Box board physical performance requirements:

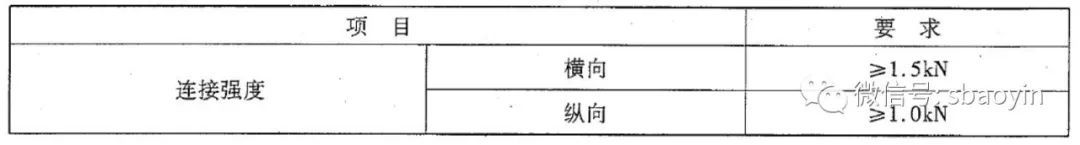

Requirements for connection strength of connecting members:

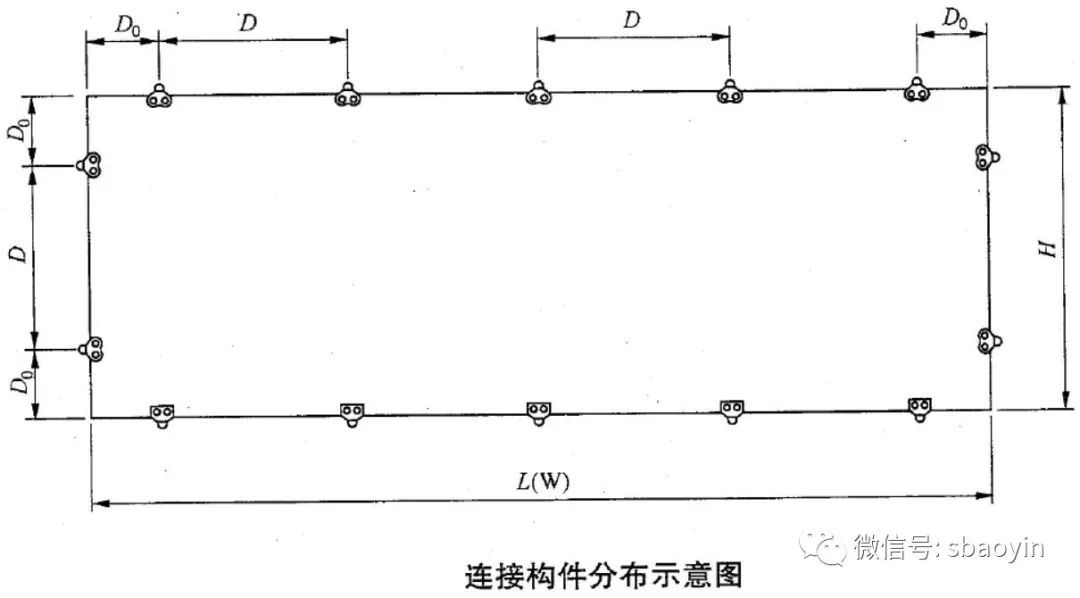

Tongue installation parameters:

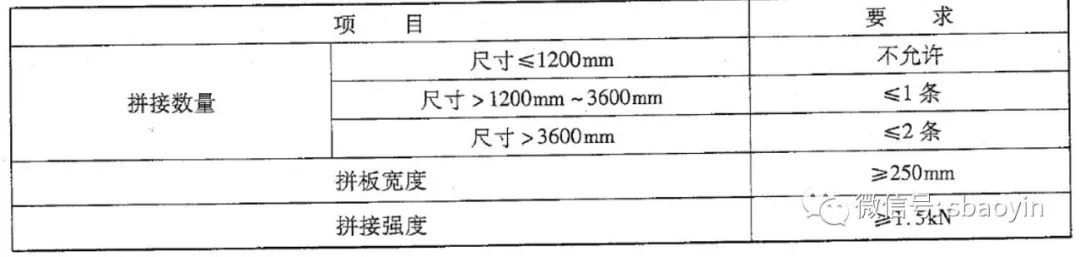

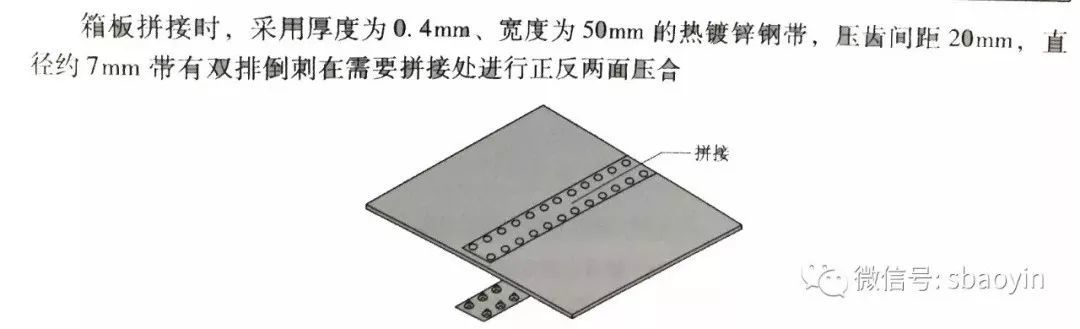

Box plate splicing parameters:

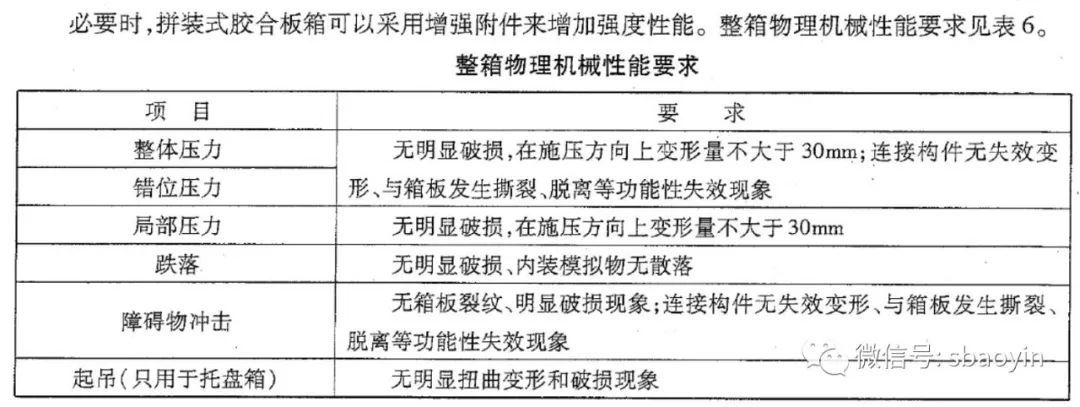

Full box of physical and mechanical performance requirements:

The product is widely used in the transportation and outer packaging of products in logistics, machinery and electronics, ceramic building materials, hardware and electrical appliances, precision instruments and meters, vulnerable goods and oversized goods. The materials meet the quarantine requirements of export commodities and avoid the tedious quarantine fumigation. It is suitable for international remote logistics. The high-temperature pressing process completely removes any harmful biological substances, and exports are free of fumigation, quarantine and commodity inspection, the export formalities can be handled with the declaration of "no wood packaging". For the export of inspection-free products, customs clearance can be smoothly carried out in the importing country.